Pulse Reverse DC Power Supply Technology for Enhanced Electroplating and Surface Finishing Control

The extremely high control accuracy and rapid switching times ensure an optimal pulse, peak precision and long-term reproducibility. Exploit the advantages of pulse technology for your company. plating electronic is your ideal, innovative and competent partner for this.

By using JEC Technology pulse DC power supplies you will get highest precision and quality, resulting in constant workpiece output and a measureable efficiency increase

- Product Details

- Technical Specification

- After-sale service

Plating reverse Rectifier Main Technical Features

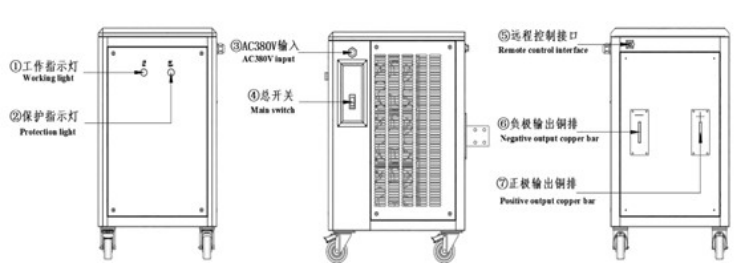

Operation mode: Remote control or manual control is optional.

Output control mode: One-way pulse and two-way pulse output control for optional.

Constant output control mode: Constant current and constant voltage control modes can be selected.

Soft start time: Soft start working time can be set in the range of 0-200s.

High control accuracy: Control accuracy ≤ ± 1%.

Rectification mode: IGBT inverter soft switch rectification, PWM pulse step modulation, IGBT chopper control mode.

Pulse pacing frequency range: 1000-8000Hz.

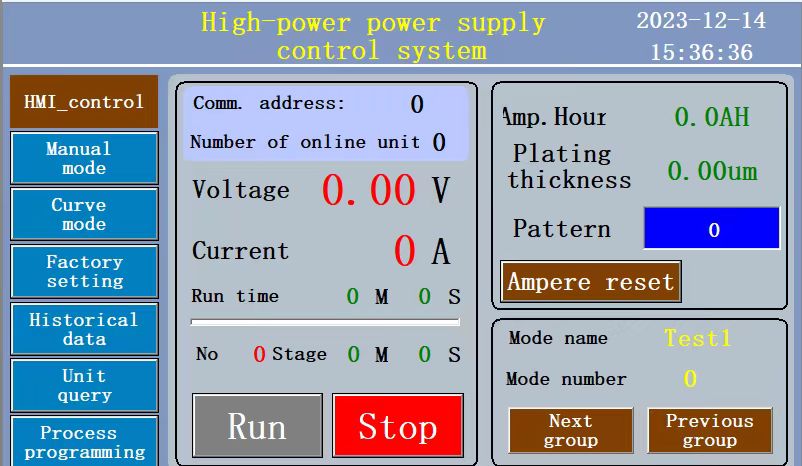

Man-machine operation interface: PLC color touch screen.

Main controller: DSP microcomputer digital trigger control, PWM pulse width adjustment control, pulse phase shift resolution ≤1μs.

Main protection functions: AC power phase loss, overvoltage, undervoltage, fast fuse blowing alarm and circuit breaker protection; output overcurrent, current limit protection, output short circuit, instantaneous overload protection; IGBT switch module, fast rectifier components, switching rectifier transformer, busbar copper bus overtemperature and overheating, fan overheating or water pressure is too high/low, blocking PWM trigger pulse protection.

Communication method: CAN bus, PROFIBUS, ETHERNET industrial Ethernet, RS485, and RS232 optical fiber communication can be configured according to customer needs to achieve remote group control or monitoring.

With 1-5 stage constant current slow rise and slow down stage number control, each stage oxidation current and oxidation time can be set separately.

Real-time recording of multiple process parameters and real-time curves such as forward and reverse current / voltage, pulse current/voltage amplitude, pulse duty cycle, pulse frequency, oxidation time, bath temperature, etc.

Remote operation control box: The remote operation control box can be configured according to the customer's site conditions, the plating rectifier and the remote control box are separated to prevent, the field operation is more convenient, and the rectifier's corrosion protection is significantly enhanced.

5 sets of process parameters can be stored or recalled to shorten the processing programming time.

Can be connected to the computer through the RS485 communication interface, or stored in the U disk and transferred to the computer, which is convenient for the customer to save the file and analyze the product process quality of the oxidized workpiece.

Workpiece coating quality: Compactness, smoothness and corrosion resistance are significantly better than ordinary plating process.

Rectifier Controller Features

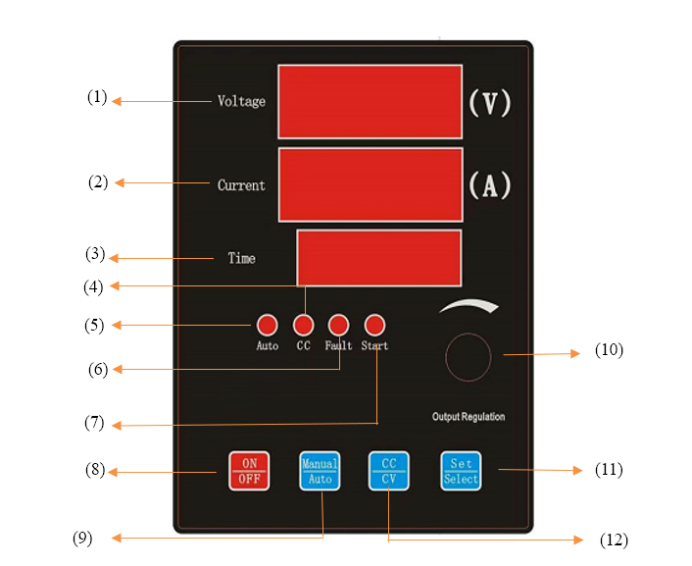

1. Voltage display window 2. Current display window 3. Time display window

4. Stable current indicator light. When the light is on, it indicates the steady flow mode. When the light is off, it indicates the voltage stabilization mode.

5. Communication interface indicator light. When the light is on, it indicates the RS485 control mode. When the light flashes, it indicates that the communication signal has been connected normally. When the light is off, it indicates panel control.

6. Fault indicator light. When the light is on, it indicates machine fault protection. At the same time, the current display window displays OC to indicate IGBT protection and OH to indicate machine overheating protection.

7. Work indicator light. When the light is on, it means the machine is in the starting state. When the light is off, the machine stops.

8. Machine start and stop button 9. Panel and RS485 control switch button 10. Voltage and current stabilization switch button 11. Function setting button 12. Voltage/current/time output adjustment encoder

External control wiring port description

Tips: The principle of pulse plating rectifier power supply

Understand the principle of pulse plating rectifier power supply can use plating rectifier more correctly. Pulse plating rectifier is a powerful method to improve the coating quality through the control method outside the tank. Compared with ordinary DC plating, it has more excellent properties (such as corrosion resistance, wear resistance, high purity, electrical conductivity, welding and good resistance to discoloration, etc.), and can greatly save rare and precious metals, therefore, it is better used in functional electroplating. At present, the square wave pulse is mostly used in pulse plating.

The pulse plating rectifier power supply can generate a square wave pulse current. When it is used in electroplating, it cannot obtain an ideal square wave, but a waveform similar to a trapezoid, which will affect the full play of the beneficial effect of the instantaneous high potential of pulse plating. The pulse frequency will also have a greater impact on the crystallization of the coating. The frequency is too low and the effect is not obvious. If the frequency is too high, the waveform distortion is large, and even the pulse current will become a DC current. The correct use of the pulse plating rectifier power supply (such as equipment installation, equipment selection, parameter selection, etc.) has an important impact on the pulse waveform, equipment reliability, and normal performance of the advantages of pulse plating.

POWER PULSE – all advantages at a glance

resources and material saving design

complex pulse waveforms

control deviation and resulting ripple < 1 %

almost upright curve shape

Meeting the requirements of the industry for smaller and more powerful printed circuit boards, the hole diameters, conductor tracks and gaps on these boards are getting smaller and smaller. With standard DC coating applications, it is not possible to meet these requirements. Here, DC pulse technology is the ideal application for coating applications to meet the demanded values on sizes and accuracy.

The pulse technology provides further optimization potential, e.g. for:

reduced cycle period

even surface with thinner coating layers

reduced secondary treatment of the workpiece

higher quality coating

Our plating power supply product comes with a comprehensive technical support and service package to ensure that our customers can operate their equipment at its optimal level. We offer:

24/7 phone and email technical support

On-site troubleshooting and repair services

Product installation and commissioning services

Training services for operators and maintenance personnel

Product upgrades and refurbishment services

Our team of experienced engineers and technicians are dedicated to providing prompt and efficient support and services to minimize downtime and maximize productivity for our customers.

Zinc Galvanic Machine 12V 3000...

Zinc Galvanic Machine 12V 3000...  Electroplating Machine High-po...

Electroplating Machine High-po...  12000A 12V Rectifier Electropl...

12000A 12V Rectifier Electropl...  Electroplating Rectifier with ...

Electroplating Rectifier with ...  Plating Machine Intelligent Au...

Plating Machine Intelligent Au...  Filter Acid and Alkali Resista...

Filter Acid and Alkali Resista...  7.5HP Corrosion Resistant High...

7.5HP Corrosion Resistant High...  SPF Series Plating Filter Pum...

SPF Series Plating Filter Pum...  Electroplating Production Line...

Electroplating Production Line...  Full Automatic Rack Type Hangi...

Full Automatic Rack Type Hangi...  Manufacturer Electroless Nicke...

Manufacturer Electroless Nicke...  Customized Electroplating Barr...

Customized Electroplating Barr...